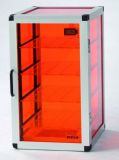

Bohlender Sicco exsiccatoren & gloveboxen

Bohlender Sicco exsiccatoren werden in de vroege 20ste eeuw ontwikkeld door de Duitse ingenieur Wilhelm Bohlender, die op zoek was naar een effectieve manier om stoffen te drogen zonder dat vocht of lucht de resultaten beïnvloedden. In 1922 introduceerde hij de eerste exsiccator, die een constante lage luchtvochtigheid handhaafde. Het apparaat werd snel populair in laboratoria & onderzoek omgevingen door zijn precisie & betrouwbaarheid.